Mar-2023

Advances in carbon capture and hydrogen technologies

Carbon capture and hydrogen purification technologies can significantly reduce CO2 emissions and support the growing hydrogen economy.

Mei Chia

Honeywell UOP

Viewed : 6667

Article Summary

Carbon capture and storage is essential to achieve net zero by 2050. Today, 15 million tons per year of CO2 is being captured and used in storage/utilisation applications through Honeywell’s CO2 Solutions process expertise. Current customers have the capacity to capture 40 million tons of CO2 per year through installed projects worldwide that utilise Honeywell CO2 technology.1 Most of these projects are in North America and Europe due to the combination of supportive policy with developing infrastructure for the transport of CO2 together with suitable locations for long-term storage.

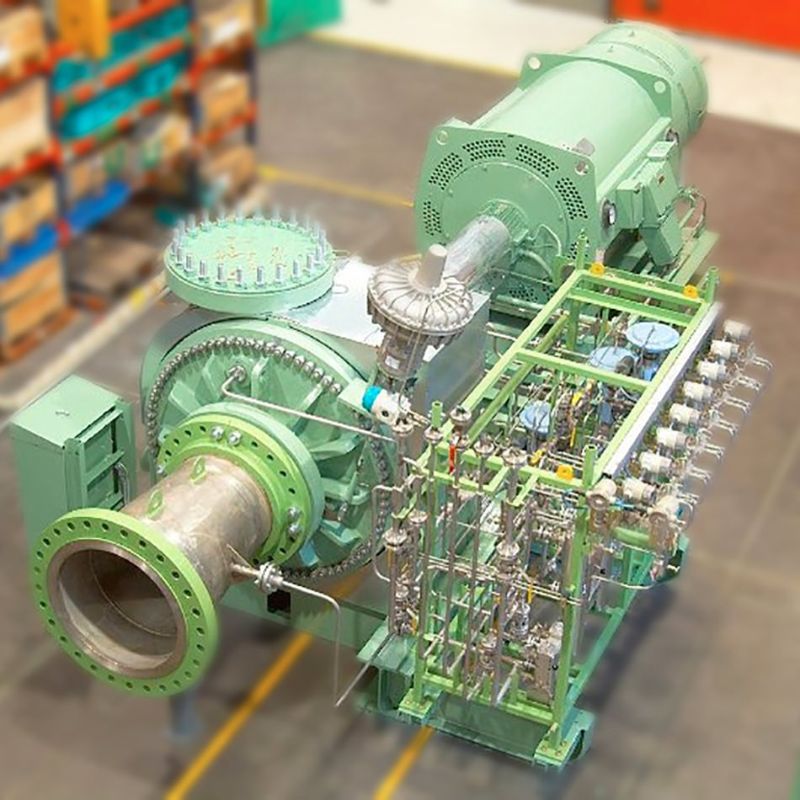

Carbon capture can be applied for post-combustion capture from power plants and natural gas. Honeywell’s UOP division has over five decades of experience in upstream gas processing, with a broad portfolio of technologies, including cryogenic technologies, pressure swing adsorption, molecular sieves and solvents, for the separation of CO2 from the natural gas stream. The company is now applying this experience to capturing CO2 from post-combustion flue gases (see Figure 1).

Advanced solvent for carbon capture

Honeywell recently announced a collaboration with Dr Gary Rochelle from the University of Texas (UT), Austin and has licensed its advanced solvent technology for its own use. Combining UOP’s process development experience with Dr Rochelle’s expertise in chemistry will accelerate the commercialisation of this technology, which can be retrofitted within existing plants or included in new unit designs.

Honeywell UOP carbon capture technologies help customers capture 15 million tons of CO2 per year, equivalent to the emissions of more than 3 million cars on the road.2 The higher efficiency allows the unit designs to be smaller and lower cost, resulting in project economics that are viable under the current CO2 policy frameworks in North America and Europe.

Carbon capture technology is an important lever to reduce emissions from energy-intensive industries such as steel and cement as well as power. CCUS capacity must increase more than 20 times to enable the capture of 840 Mt/a CO2 by 2030, in line with the IEA Sustainable Development Scenario. However, enabling policies are not yet in place in many countries.

Active projects

While projects in North America and Europe have proven the concept, implementation in Asia will be key to achieving the UN’s climate goal whilst being the biggest obstacle to overcome. Recently commissioned coal power capacity in China, India, and Vietnam will continue to operate for the next 2-3 decades. Retrofitting coal power plants with carbon capture is one option, but another more sustainable option may be to transition coal power plants to natural gas with carbon capture.

Onshore in places such as West Texas and offshore, such as in the North Sea near Scotland, natural gas streams have a high CO2 concentration. UOP membranes have been used to separate CO2 from natural gas for many years. Typically, the CO2 is reinserted into the wells, while the higher-purity natural gas is fed into the pipeline system. Wells in these locations are associated with basaltic rock formations where there is evidence that the CO2 is converted to carbonates, leading to geologically permanent sequestration of the carbon.

UOP is now applying its know-how to a number of CCS opportunities in Australia and S.E. Asia (Malaysia and Indonesia). These are mainly offshore and, again, the natural gas has a high CO2 concentration, and the gas wells are associated with basaltic formations, allowing long-term sequestration and storage. Other countries, such as Korea, lack suitable sites for storage and will need to export the CO2. To deliver similar solutions in these locales, the infrastructure and ecosystem need to be developed, requiring investment in infrastructure, including pipelines for transporting the captured CO2 and access to suitable sites for long-term sequestration (see Figure 2).

Indeed, partnerships between companies and the government are important enablers in accelerating the process. While UOP brings know-how and experience in carbon capture to the table, it also works with partners with expertise relating to CO2 transport infrastructure as well as those who manage the storage sites. While industry can take the lead, government support is critical. Over in the US, for instance, the Mississippi Legislature introduced House Bill 1214 to permit the change in the use of existing pipelines and reservoirs to allow carbon capture and storage in addition to enhanced oil recovery. Another example is the use of incentives such as the US Government 45Q tax credits for industries to store CO2 rather than emit it to the atmosphere. These provide the necessary incentives for the carbon sequestration technology to be deployed en masse.

Developing a hydrogen economy

Carbon capture is also a facilitator for developing a hydrogen economy. Between now and 2030, carbon capture will be added to existing steam methane reformers, changing grey hydrogen to blue hydrogen. This is a straightforward option using currently available technology to produce hydrogen with the lowest carbon intensity (see Figure 3).

In December 2022, Honeywell UOP and Johnson Matthey (JM) announced a new partnership to advance lower-carbon hydrogen solutions. This partnership integrates JM’s innovated LCH technology with Honeywell’s carbon capture technology to further reduce the carbon intensity of blue hydrogen. With the evolving legislative environment, an integrated solution was identified with low carbon intensity as a key target. According to JM-UOP calculations, the result is a solution which will enable Scope 1 emissions to be less than 0.1 kgCO2/kgH2 by carbon capture rates above 99%, supporting the eligibility for production tax credits within the IRA, meaning projects can access the support they need to be deployed rapidly. The solution is available at scale and provides eligibility for production tax credits within the US Inflation Reduction Act of 2022 (Honeywell, 2022).

After 2030, this begins to change as capacity in both renewable electricity and electrolysis (for green hydrogen production) is added. In the 2030-2040 timeline, we will need both blue and green hydrogen as replacement sources of fuel.

The carbon intensity of the electricity mix used for the electrolysis of water to produce the hydrogen determines the carbon intensity of the hydrogen produced. The largest electrolysers today are around 100 MW. Green hydrogen will approach cost parity with blue as the capital cost of electrolysers comes down and as the technical capacity of electrolysers increases. Then the cost of renewable power will also play a role.

The latest range of membranes for electrolysis, developed by UOP, will reduce the capital cost by around 29%.3

Sponsor:

Add your rating:

Current Rating: 5