Nov-2023

Paving the way to low-carbon propylene from the FCC unit

With the demand for propylene expected to increase in the petrochemical industry, new technology is required to process it and reduce CO2 emissions.

Bani H Cipriano, Clint Cooper and Stefan Brandt

W. R. Grace & Co

Viewed : 2903

Article Summary

Propylene plays a critical role in the petrochemical industry. Approximately 70% of propylene produced is used in the manufacture of polypropylene, a widely used polymer in durable goods and packaging, among other uses. The demand for propylene is projected to increase by 36% through 2030 (or 4% annualised) (Wood Mackenzie, 2022). One challenge associated with meeting the increased demand for propylene is the CO₂ emitted during its production. The production of propylene and ethylene is estimated to generate 250-300 million metric tons (MTs) of CO₂ per year. Since the annual demand for propylene and ethylene combined is approximately 295 million MTs per year, the production of ethylene or propylene generates, on average, approximately 1 MT of CO₂ per MT of ethylene or propylene (Dziedziak & Murphy, 2023).

Jurisdictions are continuing to implement CO₂ taxation or increase the magnitude of their CO₂ tax with the aim to reduce emissions. Countries in the Asia Pacific, such as Singapore, are implementing new carbon taxes (Gupta, Tan, Ho, & Hui, 2023). The carbon price in Europe has recently reached values of ~€100/MT (Twidale, Abnett, & Chestney, 2023). Against this backdrop, petrochemical feedstock producers will be challenged to reduce the carbon intensity of their production processes.

Propylene is made via different processes; the three most important are steam cracking, fluid catalytic cracking (FCC), and propane dehydrogenation (PDH). This article compares the carbon emissions of these processes and further examines the carbon intensity of propylene from the FCC unit. ZSM-5 technology is discussed, including its unique ability to increase the yield of propylene from the FCC without increasing CO₂ emissions. Finally, a life cycle analysis (LCA) for producing propylene from the FCC is presented, showing how Scope 3 emissions change when a refinery shifts operation between transportation fuels and propylene modes.

Carbon intensity of different processes

The process to produce propylene (and ethylene) involves either cracking of larger molecules (naphtha, VGO, resid, ethane, propane, butane) in the case of steam cracking and FCC or dehydrogenation of propane in the case of PDH. These reactions are endothermic and require significant amounts of energy. Table 1 shows ranges for the carbon intensity of different processes. Note that in both steam cracking and FCC, propylene is one of several products produced, so the emissions are expressed as MT of CO₂ per MT of total product produced.

Table 1 shows that refinery-based propylene has the lowest carbon intensity. The main reason is that, as a catalytic process, the FCC unit typically operates at the lowest temperature and is a more energy-efficient process for the production of olefins. Further, FCC is not equilibrium-limited: while the dehydrogenation of propane in the PDH process takes place in the presence of a catalyst, the reverse reaction is also possible, and higher reaction temperatures are required to drive the equilibrium towards propylene (Stitt, Jackson, & King, 1999). As a result, the FCC has the lowest reaction temperature. CO₂ emissions generated in propylene production processes stem from heating feedstocks to the required reaction temperatures: the higher the temperature, the larger the energy requirement and CO₂ emissions generated. Some of this energy is provided by burning coke produced in these processes (in the case of the FCC unit, most of the energy is supplied this way; more on this below).

The implication of Table 1 is striking. If lowering emissions were the sole metric in determining the preferred method for producing propylene, it would be preferred to source propylene from the refinery. In practice, it is not so simple since the refinery and the FCC unit are traditionally geared towards producing fuels.

FCC chemistry: Coke generation and propylene production

The FCC unit requires the production and combustion of coke to generate the heat required to vaporise the feedstock and drive the endothermic cracking reactions taking place in the riser. The combustion of this coke in the FCC unit accounts for approximately 15-20% of the CO₂ emissions from the refinery (Gudde, Larive, & Yugo, 2019) (Jing, et al., 2020).

The coke produced in the FCC unit stems from several contributors:

ΠHydrogen redistribution reactions in the catalytic cracking

Cracking of heavy feed components

Ž Poor feed vaporisation

Dehydrogenation reactions catalysed by contaminant metals in the feed

Unstripped hydrocarbons entrained in the catalyst entering the regenerator.

The coke yield directly contributes to the Scope 1, or direct, CO₂ emissions from the FCC unit. Factors that increase the coke yield (for example, operating at a higher reaction temperature) will increase emissions from the FCC unit. Reducing FCC unit severity (lowering the riser temperature), reducing the catalyst-to-oil ratio (C/O) (for example, by increasing the feed temperature and reducing catalyst cooler duty), or reducing slurry or light cycle oil (LCO) recycle rates will all reduce CO₂ emissions from the FCC unit, accomplishing the objective of reduced Scope 1 CO₂ emissions. However, these moves typically lead to reduced conversion and increased slurry from the FCC unit. While it may be desirable to operate the FCC unit at lower direct emissions by decreasing the coke yield, this is generally not economically attractive.

The yield of propylene from the FCC unit can be increased by:

ΠIncreasing reaction temperature

Increasing the C/O ratio

Ž Decreasing the hydrocarbon partial pressure (introducing additional steam into the process)

Improving feed quality,

Reformulating the catalyst to drive propylene yield higher

‘ The use of ZSM-5 technology.

Options 1-3 will either increase coke yield or require additional energy, thereby increasing emissions from the process, whereas ZSM-5 technology usage has a neutral effect on CO₂ emissions (the catalyst itself can be reformulated to minimise changes in coke yields). The effect of changing operational variables and the impact on CO₂ emissions and propylene production is shown in Table 2.

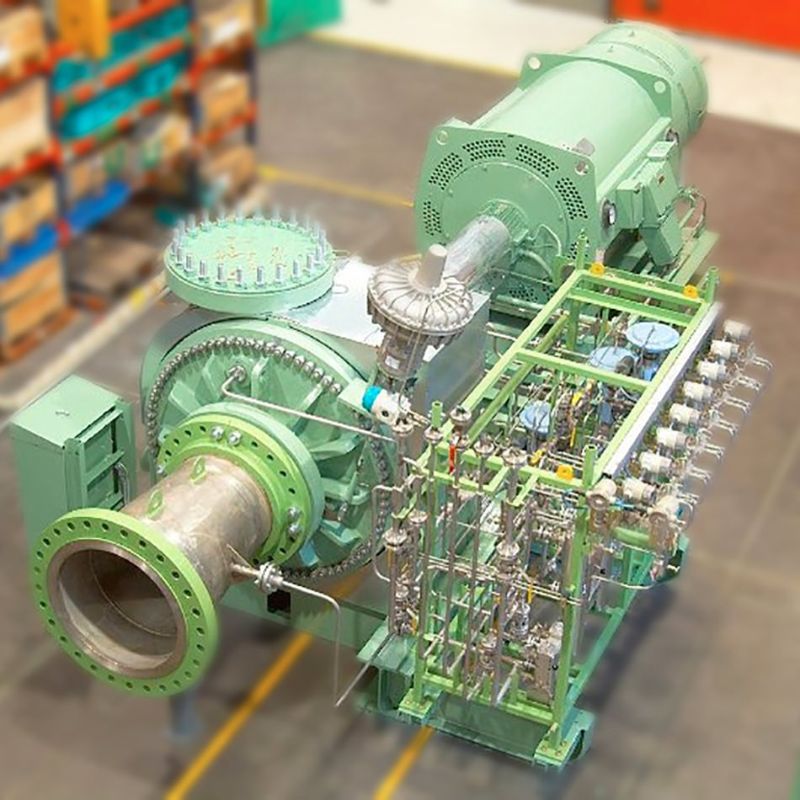

ZSM-5 technology is key to increasing propylene yield from the FCC. This shape-selective zeolite cracks gasoline-range molecules predominantly into LPG olefins (Dwyer & Degnan, 1993). In general, to maximise propylene and FCC gasoline RON, the preferred base catalyst generates and preserves the maximum yield of gasoline-range olefins so these can be further cracked by the ZSM-5 technology into propylene. The concept is illustrated in Figure 1, showing the catalytic approach to maximise LPG olefins from the FCC.

Sponsor:

Categories:

Add your rating:

Current Rating: 5